Tungsten and the Chip Supply Chain

The compute ceiling isn't just about energy. It's also about stuff—the physical materials that go into making chips. And one of the most critical, least discussed materials is tungsten.

Tungsten is everywhere in semiconductors. It's in the interconnects that wire transistors together. It's in the contact layers that connect transistors to those wires. It's in the barrier layers that prevent different materials from migrating into each other. A modern chip might have kilometers of tungsten wiring packed into an area the size of a fingernail.

And about 80% of the world's tungsten comes from China.

This is a problem. Not a future problem. A now problem. The material constraints on AI aren't just energy. They're also the atoms we need to build the machines that do the thinking.

Why Tungsten Matters

Tungsten has the highest melting point of any pure metal: 3,422°C. It has excellent electrical conductivity for a refractory metal. It's hard, dense, and chemically stable. These properties make it nearly ideal for certain critical applications in chip manufacturing.

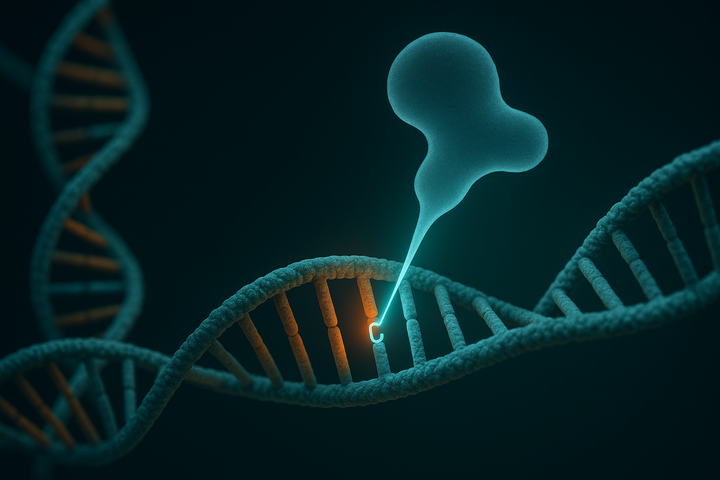

In early semiconductor technology, aluminum was the primary interconnect material. As chips got smaller, copper replaced aluminum for most wiring because of its better conductivity. But copper can't do everything. At the very small scales where transistors meet wires, and where different metal layers need to be separated, tungsten is essential.

Contact layers: Where transistors connect to the first layer of metal wiring, tungsten fills tiny holes called vias. These contacts need to be reliable, conducting current repeatedly for years without degrading. Tungsten's stability makes it the material of choice.

Barrier and liner layers: Copper tends to diffuse into silicon, destroying transistor function. Tungsten nitride and tungsten-based materials act as barriers, keeping copper where it belongs.

Gate electrodes: In some transistor designs, tungsten forms part of the gate structure that controls current flow. Its work function (how it interacts with electrons) can be tuned to optimize transistor performance.

For an advanced logic chip—the kind used in AI accelerators—tungsten consumption has been increasing with each generation. Smaller transistors mean more transistors per chip, more transistors mean more contacts, more contacts mean more tungsten.

The Concentration Problem

China dominates tungsten production more thoroughly than it dominates almost any other critical mineral. The numbers are stark:

- China produces approximately 80% of the world's tungsten concentrate. - China controls even more of the world's tungsten processing—refining raw ore into the pure forms used in manufacturing. - The next largest producers—Vietnam, Russia, Rwanda—together account for less than 15%.

This concentration happened gradually over decades. Tungsten mining is dirty and difficult; high-grade deposits are rare. Chinese mines, with lower labor costs and fewer environmental restrictions, outcompeted Western operations. Many non-Chinese mines closed in the 1990s and 2000s.

The result is a supply chain that routes through a single point. No matter where chips are designed or assembled, the tungsten in them likely came from or through China.

This creates vulnerability. If China restricts tungsten exports—as it has already done with gallium and germanium, two other semiconductor-critical materials—the global chip industry feels immediate pain.

The 2023 Warning Shot

In July 2023, China announced export restrictions on gallium and germanium, two specialty metals used in compound semiconductors (different from the silicon chips that use tungsten, but part of the same ecosystem). The restrictions required export licenses, creating uncertainty and leverage.

The move was widely interpreted as retaliation for Western restrictions on chip manufacturing equipment exports to China. Tit for tat in the technology cold war.

Gallium and germanium aren't tungsten, but the warning was clear: China can use its critical mineral dominance as a weapon. If it chose to restrict tungsten exports, the impact on semiconductor manufacturing would be severe.

As of early 2025, China hasn't imposed tungsten restrictions. But the threat shapes industry planning. Companies are scrambling to diversify supply chains, restart mothballed mines in friendly countries, and develop alternative materials.

None of this happens quickly. Mining projects take years from decision to production. Alternative materials require extensive qualification before they can be used in chip manufacturing. The dependency built over decades can't be unwound in months.

The Broader Critical Minerals Picture

Tungsten is one piece of a larger critical minerals puzzle. Modern technology depends on dozens of elements, many with concentrated supply chains.

Rare earth elements: Essential for magnets in electric motors, hard drives, and many electronics. China controls about 60% of mining and 90% of processing.

Cobalt: Used in batteries and some semiconductor applications. The Democratic Republic of Congo produces about 70% of global supply, much of it processed through Chinese-owned operations.

Lithium: The battery metal, with production concentrated in Australia, Chile, and China, but processing dominated by China.

Neon: Used in lithography lasers. Ukraine produced about half of global supply before the 2022 Russian invasion, leading to price spikes and scrambles for alternatives.

Each of these represents a potential chokepoint. Each could constrain the pace of AI development if supply is disrupted. The chip industry has spent decades optimizing for efficiency and cost, outsourcing to the lowest bidder. Only now is it reckoning with the vulnerabilities this created.

The Physical Limits of Scaling

Here's a deeper point: even without geopolitical disruption, material constraints are becoming real limits on chip manufacturing.

As transistors shrink toward atomic scales, the amount of material per transistor decreases, but the number of transistors increases faster. Total material demand keeps rising. And some materials face fundamental scarcity.

Extreme ultraviolet lithography (EUV), the technology that patterns the smallest features on modern chips, requires tin droplets to generate the UV light. Tin isn't scarce, but the precision required is extraordinary. Any contamination, any supply disruption, and the world's most advanced chip manufacturing stops.

Helium is needed for cooling and leak detection in semiconductor fabs. Helium is created by radioactive decay and accumulates in natural gas deposits. It's finite; we can't make more. Global helium supply has experienced periodic shortages.

Ultrapure water is required in enormous quantities to rinse wafers during manufacturing. A single chip fab might use millions of gallons per day. In water-stressed regions like Taiwan, where TSMC manufactures most of the world's advanced chips, drought becomes a semiconductor crisis.

The compute ceiling isn't just about energy and efficiency. It's about the physical substrate of computation itself. Every chip is made of atoms, and atoms come from mines.

Geopolitics of Compute

The critical minerals picture reveals how deeply AI development is embedded in geopolitics.

The United States has chip design leadership but depends on Asian manufacturing. Taiwan makes most advanced chips; South Korea makes most memory. Both are within China's sphere of influence or potential military threat.

China has manufacturing capacity but lags on cutting-edge technology—a gap Western export controls aim to maintain. But China dominates the raw materials that both Chinese and Western chip industries need.

Europe has sophisticated equipment manufacturers (ASML in the Netherlands makes EUV machines) but limited chip manufacturing and heavy mineral dependency.

No single country or bloc has self-sufficiency. The chip supply chain is a network of mutual dependencies and vulnerabilities. Disrupting any node—mines in China, fabs in Taiwan, equipment in the Netherlands—cascades through the entire system.

This interdependence is sometimes called "mutual assured economic destruction"—the idea that disrupting supply chains would hurt everyone, including the disruptor. But this logic only holds as long as all parties are rational economic actors. In a world of rising nationalism and great power competition, economic rationality isn't guaranteed.

AI accelerates these tensions. As chips become instruments of national power—enabling military AI, surveillance, economic advantage—control of chip supply chains becomes a security imperative. The race for AI is, partly, a race for the minerals and machines that make AI possible.

What's Being Done

The vulnerability is recognized. Actions are underway—though whether they're fast enough remains uncertain.

CHIPS Act and allied initiatives: The United States passed the CHIPS and Science Act in 2022, providing $52 billion for domestic semiconductor manufacturing. The EU and Japan have similar programs. The goal is to reduce dependence on Taiwan and Asia for chip fabrication.

Critical minerals agreements: The US and allies are negotiating agreements to secure critical mineral supply chains. Australia, Canada, and African nations are targets for investment in mining and processing.

Stockpiling: Some countries and companies are building strategic reserves of critical materials. This provides buffer against short-term disruption but doesn't solve long-term dependency.

Alternative materials research: Semiconductor companies are exploring alternatives to concentrated-supply materials. Ruthenium could potentially replace tungsten in some applications. Cobalt-free battery chemistries are being developed. But qualifying alternatives takes years, and some materials have no practical substitutes.

Recycling: Electronics contain valuable materials that can be recovered. But recycling rates for most metals are low, and recycling can't satisfy growing demand—only slow depletion.

None of these solutions is quick or complete. The dependencies built over decades will take decades to unwind, if they can be unwound at all. In the meantime, chip supply chains remain vulnerable.

The Atom Economy of Intelligence

Step back to the big picture. We've talked about the energy cost of computation. Now add the material cost.

Every AI chip—every GPU training large language models, every TPU running inference—required mining, refining, manufacturing. Tungsten from Chinese mines. Silicon from purified sand. Copper from South American deposits. Rare earths from a handful of sources.

Intelligence is an atomic achievement, not just an energetic one. The substrate matters. The stuff matters.

This adds another dimension to the compute ceiling. Even if energy were unlimited and free, chip manufacturing would still face material constraints. Mines take time to open. Refining capacity takes time to build. Alternative materials take time to qualify.

The pace of AI development depends not just on algorithmic breakthroughs or energy supply, but on the mundane physics of digging metals out of the ground and turning them into nanometer-scale structures.

What This Means

The tungsten story illustrates a broader truth: AI is not purely digital. It's physical all the way down.

The cloud runs on metal. Machine learning requires machines. Artificial intelligence is instantiated in atoms arranged in particular configurations, manufactured in specific facilities, powered by particular energy sources, built from materials pulled from particular mines.

Ignoring the physical substrate is a form of magical thinking. The "weightless economy" was always an illusion; information processing has mass and requires infrastructure. AI is bringing this back into focus.

The compute ceiling forces attention to every link in the chain: energy generation, chip manufacturing, material supply. Solving the energy problem but hitting a tungsten shortage still stops progress. Building fabs but running out of ultrapure water still stops progress.

The future of intelligence depends on supply chains as much as on algorithms. This isn't the glamorous part of AI development. But it might be the binding constraint.

There's a lesson here that goes beyond AI. Every technological system is embedded in physical reality. Every leap in capability depends on material foundations. The information revolution is made of matter. The knowledge economy is dug from the earth.

Tungsten is a reminder. When you use an AI system, you're not just running software. You're activating a physical artifact—atoms arranged with extraordinary precision, manufactured through global supply chains, dependent on mines in distant countries and refineries you've never heard of. The intelligence is real. So are the atoms that instantiate it.

Further Reading

- U.S. Geological Survey. (2024). "Mineral Commodity Summaries: Tungsten." - Semiconductor Industry Association. (2024). "CHIPS Act Implementation Update." - Yergin, D. (2022). The New Map: Energy, Climate, and the Clash of Nations. Penguin.

This is Part 7 of the Intelligence of Energy series. Next: "Fusion Dreams: Tokamaks Meet Training Runs."

Comments ()